331: Soft Materials

Kenneth R. ShullDepartment of Materials Science and EngineeringNorthwestern University

1 Catalog Description

Different kinds of polymeric materials. Relationships between structure and physical properties; rubber elasticity, the glassy state, crystallinity in polymers. Lectures, laboratory. Prerequisites: 301 or equivalent; 314 or CHEM 342 1.

2 Course Outcomes

3 331: Soft Materials

At the conclusion of the course students will be able to:

- Given the chemical structure of a common polymer, draw the chemical structures of the monomer(s) from which it was made.

- Given the chemical structure of a monomer (or monomers), draw the chemical structure polymers that can be synthesized from it (or them).

- Understand, describe and calculate the structural parameters of polymeric materials including monomer units, molecular weight, tacticity, coil dimension, crystallinity, and morphology.

- Describe the relationship between the above structural parameters and the mechanical and thermal properties of polymeric materials.

- Describe how the structure and mechanical properties of polymeric materials change at the glass transition temperature and at the melting temperature.

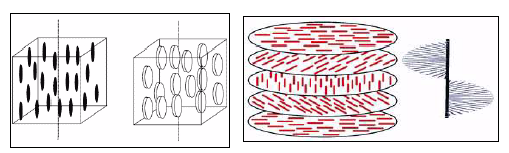

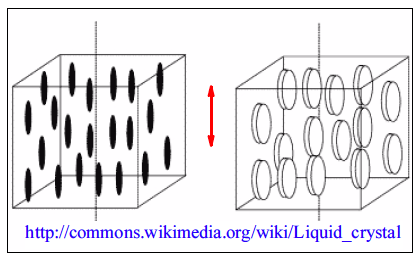

- Describe how the molecular structure of a surfactant determines its micelle structure.

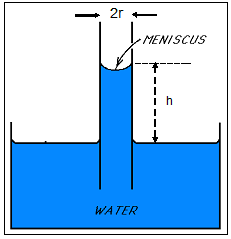

- Describe how surfactant molecules and aggregates affect the optical properties, viscosity and surface tension of polymer solutions.

- Calculate the intermolecular and surface forces for molecules and colloids of different geometries.

- Design strategies to stabilize or destabilize colloidal systems.

- Identify a soft material application in daily life, such as in arts, music, sports or food, and explain how material advancement has imporved the application.

test text

4 Introduction

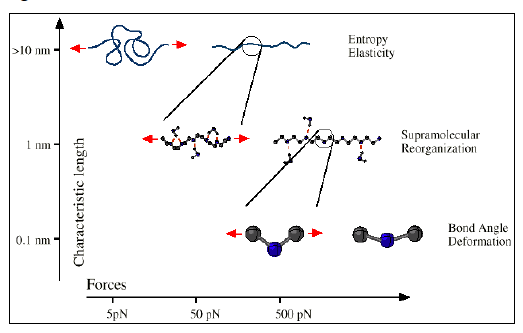

Since the title of this book contains the term 'Soft Materials', it makes sense to define what we really mean by 'soft'. Here are two ways to think about it:

- Soft Materials have Low Elastic Moduli.

By 'low' we mean significantly lower than the moduli of crystalline metals and ceramics. The jellyfish shown in Fig.

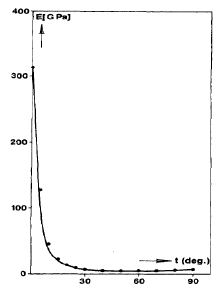

1 is obviously 'soft' in this sense. Metals and ceramics typically have moduli in the range of 100 MPa (see Fig.

2). While the strength of metals can be adjusted by a variety of mechanisms that affect the nature of dislocation motion in these systems, the modulus is set by the nature of the interatomic potentials and there nothing that can really be done to significantly affect the modulus of a given material. Polymers are different, however, and have a much broader range of elastic moduli. The stiffest of these (Kevlar™for example) have elastic moduli in at least one direction that are comparable to the modulus of steel.

- Thermal Fluctuations Matter in Soft Materials.

At a molecular level, the relevant energy scale that determines a variety of important properties is the thermal energy,

, where

is

Boltzmann's constant and

is the absolute temperature. If different molecular arrangements within a material differ in energy by an amount that of the order of

or less, than these different arrangements will all be experienced by the material. When the free energy of a material is dominated by the entropy associated with the accessibility of these different arrangements, it is possible to calculate the elastic properties of the material from the molecular structure with considerable accuracy.

Exercise: How high above the earths surface must a single oxygen molecule be lifted in order for its gravitational potential energy to be increased by ?

Solution: The gravitational potential energy is , where is the mass of the object, is the gravitational acceleration (9.8 m/s ) and is height. The mass of a single molecule is obtained by dividing the molecular weight in g/mole by Avogadro's number:

The conversion to kg illustrates the first point that we want to make with this simple calculation: Don't mix units and convert everything to SI units (m-kg-s) to keep yourself sane and avoid unit errors. Boltmann's constant, needs to be in SI units as well:

Now we just need to equate to , using something reasonable for the absolute temperature, . I'll use =300 K to get the following:

The full oxygen partial pressure is given proportional to

, so this value of

is the altitude where the oxygen pressure is a factor of

(2.7) less than the value at sea level.

5 Synthetic Polymers

Most of this book is devoted to synthetic polymers because of their widespread use and importance, and because they illustrate many of the key concepts that are relevant to natural polymers and other soft materials. We begin with a basic introduction to the synthesis of polymeric materials, and the z component is between properties of these materials. We conclude with some examples of soft materials made up of building blocks that are held together by relative weak forces.

5.1 What is a Polymer

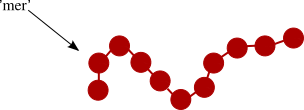

A polymer is a large molecule made from many small

or 'mers'. There is an inherent anisotropy at the molecular level because both strong and weak bonding interactions are important:

- Strong covalent bonds are formed within a molecule (between 'mers').

- Weak Van der Waals or hydrogen bonding are formed between molecules, and cause the materials to condense into a solid or liquid phase.

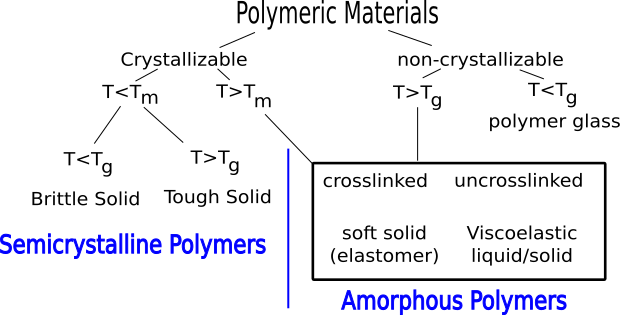

5.2 Classification Scheme

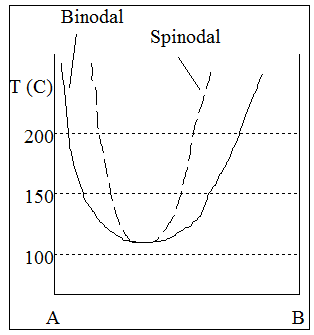

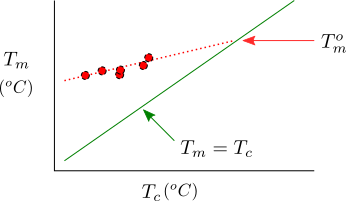

Crystallization and glass formation are the two most important concepts underlying the physical properties of polymers. Polymers crystallize at temperatures below

(melting temperature) and form glasses at temperatures below

(glass transition temperature). All polymers will form glasses under the appropriate conditions, but not all polymers are able to crystallize. The

shown in Figure

4 divides polymeric materials based on the locations of

and

(relative to the use temperature,

) and is a good place to start when understanding different types of polymers.

Elastomers

Traditional elastomers are amorphous materials with a glass transition temperature less than the use temperature so that they remain flexible. The are generally crosslinked so that they do not flow over long periods of time. Common examples are shown in Figure

5.

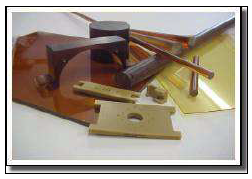

Glassy Polymers

Glassy polymers are amorphous like elastomers, but their glass transition temperature is above the use temperature. Because of this they behave as rigid solids, with elastic moduli in the range of

Pa. Glassy polymers do not need to be crosslinked, because below

the molecules and flow of the material is suppressed. Also, because the materials are homogenous over length scales comparable to the wavelength of light, they are transparent. Common examples are illustrated in Figure

6.

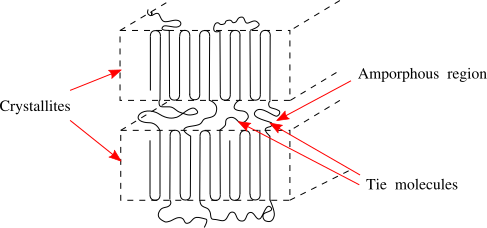

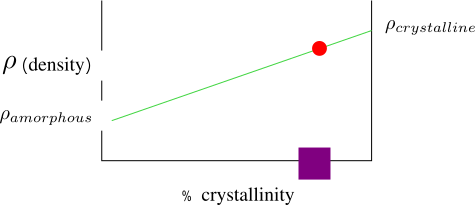

Semicrystalline Polymers

Semicrystalline polymers must have molecular structures that are compatible with the formation of an ordered lattice. Most atactic polymers are amorphous (non-crystalline) for this reason (with the exception being examples like poly(vinyl alcohol where the side group is very small). Another requirement is that

be less than

. If the glass transition temperature is higher than

the material will form a glass before crystallization can occur. In the glassy polymer the material is kinetically trapped in the glassy state, even though the crystalline state has a lower free energy below

. Examples of some semicrystalline polymers are shown in Figure

7.

5.3 Understanding Polymer Chemistry

Crystallization and glass formation processes are central to our understanding of polymeric materials, we must eventually address the following question:

- How is a polymer's tendency to crystallize or form a glass determined by is molecular structure?

Before we answer this question, however, we must answer the following question:

- What determines this molecular structure, and how are our choices limited?

In order to answer this question properly, we need to study the processes by which polymeric materials are made. Polymer synthesis involves organic chemistry. After familiarizing ourselves with some of the relevant polymer chemistry, we will be in a position to study the physical properties of polymers. For this reason, our discussion of molecular structure in polymers will include some chemistry.

5.3.1 Covalent Bonding

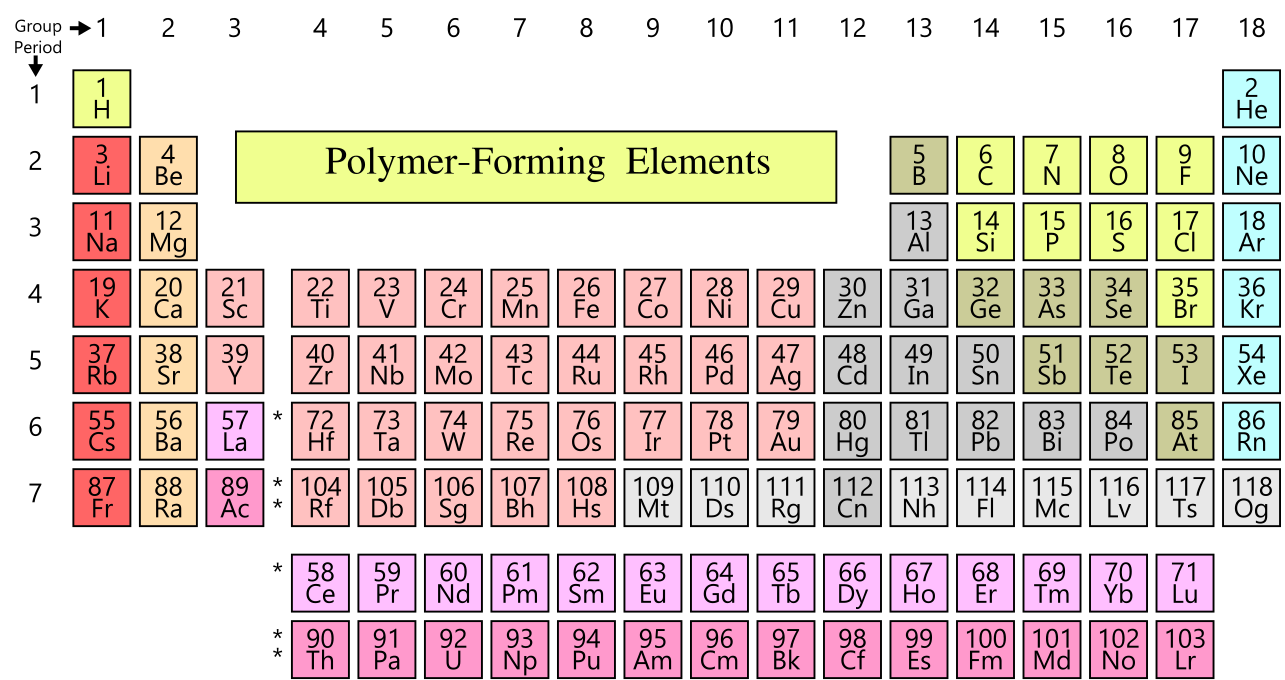

Polymer molecules consist of atoms (primarily carbon, nitrogen, oxygen and hydrogen) which are covalently bound to one another. The fraction of the periodic table that can form strong covalent bonds is relatively small, corresponding to the ten atoms shown in yellow in Figure

8 (H, C, N, O, F, Si, P, S, Cl, Br). It is useful at this point to recall some of the basic principles governing the bonding between these atoms:

- Nitrogen, oxygen, carbon and the other covalent bond forming atoms with (F, Si, P, S, Cl, Br) are surrounded by 8 electrons, included shared electrons.

- Hydrogen atoms are surrounded by 2 electrons, included shared electrons.

- A single bond involves two shared electrons, a double bond involves 4 shared electrons, and a triple bond involves 6 shared electrons.

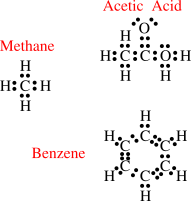

5.3.2 Lewis Diagrams

Lewis diagrams (

Wikipedia link) provide a convenient way of keeping track of the valence electrons in covalently bonded compounds. Several examples are given here. Note how the rules given on the previous page are followed in each case.

5.3.3 Bonding

The following principles of covalent bonding in organic materials are very helpful:

- Carbon, Silicon: group 14 (4 valence electrons) - 4 more needed to complete shell -

C, Si form 4 bonds with neighboring atoms

- Nitrogen, Phosphorous: group 15 (5 valence electrons) - 3 more needed to complete shell -

N, P form 3 bonds with neighboring atoms

- Oxygen, Sulfur: group 16 (6 valence electrons) - 2 more needed to complete shell -

O, S form 2 bonds with neighboring atoms

- Hydrogen (group 1) or Fluorine, Chlorine, Bromine (Group 17):

Fl, Cl, Br form 1 bond with neighboring atoms

(The situation for P and S is actually a bit more complicated when either of these atoms are bonded to oxygen, but these general rules serve our purpose for now.) The chemical structures throughout this book can be seen to obey these rules.

5.3.4 Shorthand Chemical Notation

Most of the chemical structures illustrated in this text are relatively simple, consisting of single and double bonds between atoms. We generally don't bother to write all of the carbons and hydrogens into to the structure. We use the following common conventions.

- If no element is included, element at junctions between different bonds are assumed to be carbon.

- If atoms are missing, so that the rules given above for the number of bonds attached to each atom type are not satisfied, the missing atoms are hydrogens.

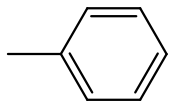

An example of this convention is shown below in the structure for

:

:

Note the resonance between the two possible ways of drawing the double bonds in the drawing on the left. Molecules with these types of alternating

.

6 Polymerization Reactions

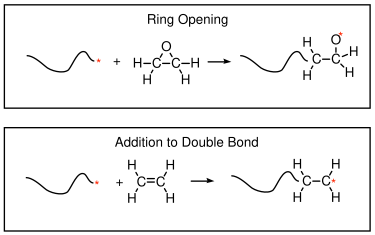

Polymerization is the process by which small molecules react with one another to form large polymer molecules. Polymerization reactions can be broken up into the following two general categories:

Step Growth Polymerizations:

Collections of A and B species react with one another. In linear step growth polymerizations, the ends of molecules react with one another to form longer molecules. A variety of reactions are possible, so you need to know at least a little organic chemistry. We'll focus on just a few of the most common cases.

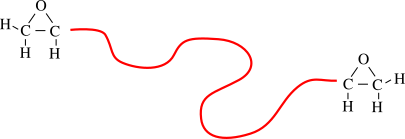

Chain Growth Polymerizations:

Each polymer chain has one reactive site to which additional monomers are added.

Additional Resource:

The Macrogalleria web site has some excellent, simple descriptions of polymerization reactions. Specific examples are referenced at different points throughout this book.

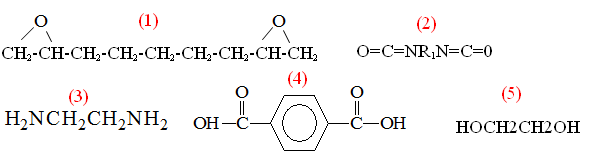

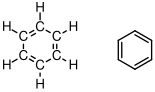

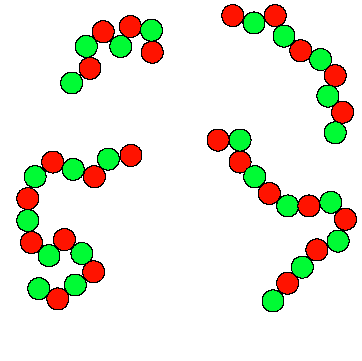

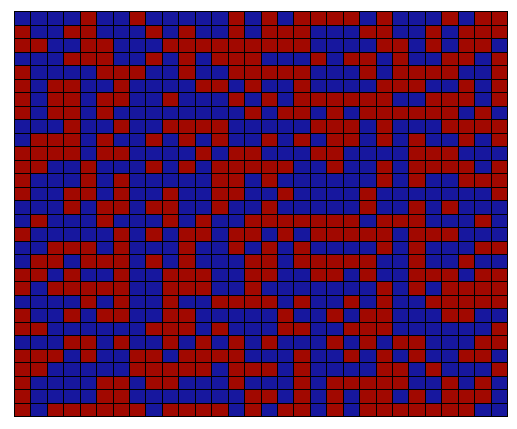

6.1 Step-Growth Polymerizations

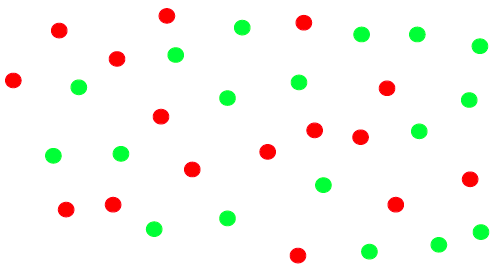

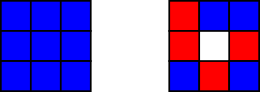

In this example green and red monomers can only react with each other. Because there are 5 more red monomers than green monomers, there are 5 molecules remaining at the end of the reaction, with each of these molecules possessing two red end groups. The extent of reaction,

is defined as the fraction of available reactive groups which have actually undergone a reaction.

Values close to one are needed in order to obtain useful, high molecular weight polymer. A delicate stoichiometric balance generally needs to be maintained (same amount of red and green monomers) in order to obtain high molecular weight.

The following pages illustrate some of the specific reactions which take place during the polymerization process. To illustrate the concepts involved, we consider the following polymer types, all of which are produced by step-growth polymerization:

- Section 6.1.1

- Section 6.2.1

- Section 6.2.2

- Section 6.2.3

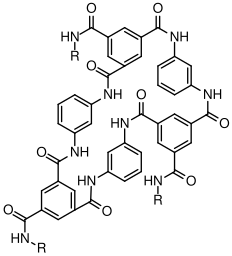

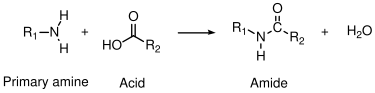

6.1.1 Polyamides

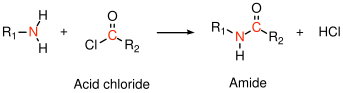

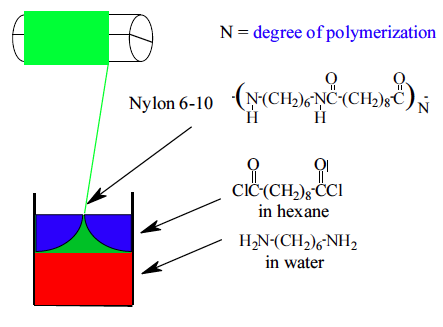

In this example, a primary amine reacts with a carboxylic acid to form an amide linkage. Water is liberated during the condensation reaction to form the amide. Primary amines and acid chlorides undergo a similar reaction:

Acid chlorides react very rapidly with amines at room temperature, which is very useful for demonstration purposes. Acid chlorides can also react with water to form carboxylic acids, however, and commercial polyamides are generally produced by reaction with carboxylic acids.

6.2 Interfacial Polymerizations

6.2.1 Polyesters

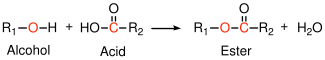

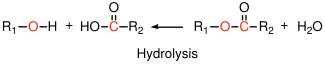

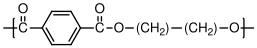

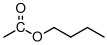

Polyesters can be formed by condensation reactions of alcohols with carboxylic acids:

Polyethylene terephthalate (Mylar, Dacron, 2L soda bottles) is a common example. Note that under appropriate conditions, the reverse reaction (hydrolysis)

reaction can also take place, where the addition of water to an ester bond forms the acid and the alcohol. This reaction is important in a variety of polymers used in biomedical applications, which degrade in the body via hydrolysis of the polymer. Polycaprolactone is one example.

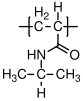

6.2.2 Polyurethanes

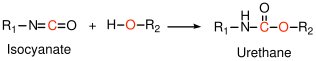

Polyurethanes are formed by the reaction of isocyanates with alcohols, as shown below:

Note that this is NOT a condensation reaction, since no byproducts are formed during the reaction. Also note that the urethane linkage contains an oxygen atom in the backbone, whereas the amide linkage does not. (The and substituents can have different structures, but are always attached to the illustrated linkages by carbon atoms.)

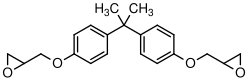

6.2.3 Epoxies

All epoxies involve reactions of epoxide groups (3-membered rings containing an oxygen atom) with curing agents. Amine curing agents are very common, as illustrated Figure , which shows a primary amine reacint with an epoxide group).

The secondary amines which remain can react with additional epoxide groups to form a branched structure as shown in Figure

19. The reactive functionality of a primary diamine is 4 when the reaction is with an epoxide (as opposed to its functionality of 2 in the case where the diamine reacts with an acid or acid chloride).

7 Molecular Weight Distributions

The repeat unit for this polymer consists of a red and green unit together. The degree of polymerization

(

) is the number of repeating units for a single molecule. Because of the statistical nature of the reaction process, not all molecules at any given point in the polymerization will have the same size. This point is illustrated in Figure

20, which shows schematic representations of polymer with and

. The molecular weight,

, of a polymer is obtained from

by multiplying by

, the molecular weight of a repeating unit of a polymer chain:

|

Some key definitions:

: Degree of polymerization - the number of repeat units in a single molecule

: Molecular weight - molecular weight of a polymer molecule (g/mole)

Molecular weight per repeat unit (g/mole)

|

The complete distribution of molecular sizes can be described by a histogram. There are two different quantities that we can keep track of: and , which are defined as follows:

- : number of molecules with degree of polymerization =

- : weight of all molecules with degree of polymerization =

The total number of molecules ( ) or total weight ( ) is obtained by summing over all possible values of :

Note: We've assumed here for simplicity that

takes on integer values. This is true for chain growth polymerizations, but for step growth polymers

can formally have non-integer values (like the value of 10.5 in Figure

20). In this case you can just imagine that distribution has divided into 'bins' of width '1'.

7.1 Number Average Molecular Weight

The

number average molecular weight

,

, is simply the total weight of all the polymer, divided by the number of polymer molecules (typically in moles):

In more formal terms, we can replace

and by the respective sums from Eqs.

7.2 and

7.3:

By dividing by the repeat unit molecular weight,

, we obtain the

number average degree of polymerization

,

:

7.2 Weight Average Molecular Weight

The

weight average molecular weight

,

, is similar to number average, but we use the distribution of weights instead of the distribution of molecules:

The

weight average degree of polymerization

,

, is obtained simply by dividing

by

,

i.e. The

, given by

/

must be greater than or equal to one. Polymers with a polydispersity index close to 1 are said to be monodisperse, with a narrow distribution of molecular weights. While Eq.

7.7 is useful in a formal sense, it's a bit cumbersome to use. Suppose we have a series of molecular weight fractions, with

between the weight of each fraction and

being the weight average molecular weight of each fraction. The weight average molecular weight for this collection of molecules is given by the following summation:

Exercise:

Suppose 3g of a monodisperse polymer with M=50,000 g/mol is blended with 5g of a monodisperse polymer with M=85,000 g/mol. What are the values of , and the polydispersity index for the resultant mixture?

Solution:

To get , we need to divide the total weight of polymer (3g + 5g = 8g) by n, the total number of moles of polymer molecules:

The average molecular weight is obtained from the definition of this quantity:

In our example, we obtain the following:

Polydispersity Index =

Exercise:

What if the polymers in the previous example are not monodisperse? Suppose the molecular weights quoted are weight averages, the low molecular weight polymer has a polydispersity of 1.6, and the high molecular weight polymer has a polydispersity of 2.5.

Solution:

We divide by the polydispersities to get number average molecular weights, and use these values to get the total number of molecules:

Due to the form of the expression for the average molecular weight, we can modify the standard expression for the Mw by summing over all different components of the blend, and using the weight average molecular weight for each component:

In our case is the same as it was in the previous example:

Polydispersity index =

7.3 Molecular Weight Evolution during Step Growth Polymerization

Suppose moles of difunctional A molecules with molecular weight react with difunctional B molecules with molecular weight in a step growth polymerization. If > , then all of the B molecules can react, and molecules will remain at the end of the polymerization:

For condensation reactions, a mole of condensation product with molecular weight material as a wholeecule of B that reacts. The total weight, , of polymer produced is:

The maximum number average molecular weight, , is obtained by using this value for , an setting equal to :

For high molecular weight polymers, we can make some additional approximations, since know that << in this case. We can therefore simplify to the following:

The repeat unit molecular weight, is obtained by adding the molecular weights for the A and B monomers, and subtracting out the molecular weight of the 2 condensation products that are formed (since a repeat unit contains 2 A-B linkages, and therefore involves 2 condensation reactions):

From this we obtain the following expression for :

The next thing we would like to sort out is how , the total number of molecules, varies with the extent of reaction, . The trick is to realize that every time a reaction takes place, the number of molecules in the system decreases by 1. Each molecule has two groups (one at each end) that can react, and two groups take part in each reaction. For we obtain the following:

In this equation is the initial number of molecules that we start off with (when =0), and gives the decrease in the number of molecules resulting from all of the reactions that have taken place for some finite value of . The total mass of the polymer that has been produced is (ignoring the fact that the ends of all the molecules some extra mass that may potentially leave as part of a condensation product). The weight average molecular weight is simply , from which we obtain the following:

As mentioned above, the degree of polymerization that can be obtained from a homogeneous mixture of A and B monomers in a linear stop growth polymerization is limited by stoichiometry. Reaction of all A monomers requires the existence of unreacted B monomers, and vice versa. If , then some of the functional groups on either the A or B monomers must remain unreacted, so that has a maximum value somewhat less than 1. Let's consider the case where , in which case we know there are molecules left when all the B groups have reacted. Each of these molecules has an unreacted A group at each end, so there are a total of unreacted groups at the end of the reaction. At the beginning of the reaction (when =0) we had reactive groups, so the total number that have reacted is . This corresponds to a fraction of reacted groups which we refer to as :

Another way to obtain

is to use Eq.

7.17 for

, with

:

which with

is equivalent to Eq.

7.15.

From the information given so far we know how the number average degree of polymerization evolves with , but in many cases we would like to know what the full molecular weight distribution might look like. To do this we need to account for the statistics, and use the more detailed definitions for (Eq. ) and (Eq. ) A molecule formed from a linear step growth polymerization that has a degree of polymerization of was made from molecules ( of type A and of type B). Because these original molecules are all bifunctional, there are a total of reactive groups in the monomers that reacted together to form a polymer of length . Only two of these groups remain unreacted (the end groups). Because each reaction involves two groups, this means that reactions have taken place ( groups have reacted).

The key assumption is that all groups react with equal probability. This probability must therefore be equal to the fraction of functional groups which has reacted, which has already been defined as the extent of reaction,p. The probability that any single one of these reactions has taken place is therefore equal to . We have to multiply all of these probabilities together to get the probability of having a polymer with a degree of polymerization of , so we end up with the following:

The weight, , corresponding to each fraction is proportional to :

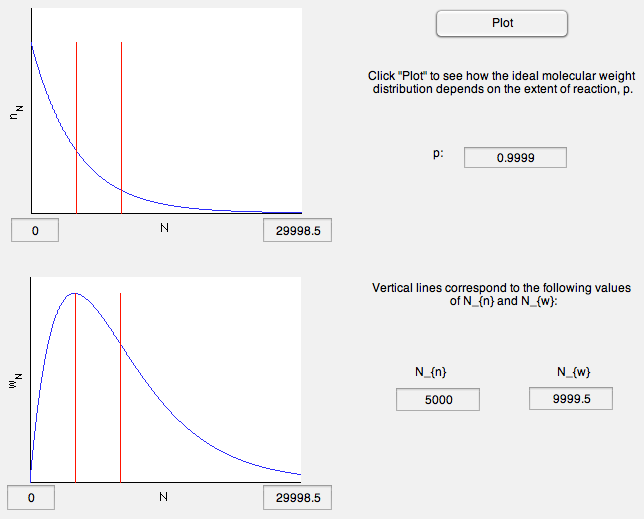

The shapes of these distributions for and are shown in the plots below, and can be replotted with different values of in the MATLAB modulue referred to below.

- What happens to the polydispersity index as the degree of polymerization increases?

- Where are the number and weight averaged degrees of polymerization in comparison to the peak in ?

- How does the shape of the molecular weight distribution change as gets very large?

- What sizes of molecules are present in the highest numbers?

- For what values of p is Nn equal to 0.5, 1, and infinity? Can you develop a simple explanation for these results? What are the values of the polydispersity for these values of p?

|

Analytic expressions can be derived for number-average and weight average degrees of polymerization for ideal step growth polymerizations that follow the distribution described by Eq.

7.20. Substitution of this expression into Eq.

7.5 gives the following for

:

We assume that our material is isotropic ,i.e., =1/2, 1, 3/2, 2, etc. Half integer values of are allowed because is the number of repeat units in the molecule. (A value of 3/2 for would correspond to a molecule with one A monomer between two monomers, for example). Alternatively, we can replace by , where takes on all positive integral values:

We can follow a similar procedure to get an expression for

. Combination of the ideal, linear step growth size distribution (Eq.

7.20) with the definition of

(Eq.

7.7), gives

we can again let so that takes on all integer values, so that the expression for becomes:

These expressions for and can be simplified by using the following mathematical formulas:

Substituting the results for these sums into Eqs.

7.23 and

7.25 results in the following:

The expression for is the same as the result that we got from the previous section, just by keeping track of the total number of molecules in the system. Calculation of is a bit more complicated though, and requires the statistical approach used in this section. For the polydispersity index we get:

Useful, high molecular weight polymers produced by step-growth polymerization are therefore have a polydispersity index that is close to 2.

8 Non-Linear Step Growth Polymerizations

Nonlinear step-growth polymerizations involve the use of monomers that have a reactive functionality,

, which is greater than 2.

8.1 Gelation

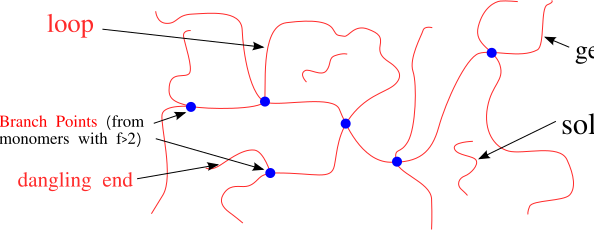

A network

(or gel) is formed when the molecular weight of the largest molecule in the system reaches infinity. Everything which is covalently attached to this single very large molecule is part of the gel fraction.

Unattached molecules which are not part of the

gel fraction make up thesol fraction

. Thegel point

refers to the point in the polymerization reaction at which point a gel fraction first appears, and the overall process is referred to asgelation

.

8.2 Prepolymers

In many cases, the length of the polymer between branch points is determined by the molecular weight of a prepolymer

. Prepolymers generally have a reactive functionality of 2.

The following factors determine the property of the network:

- Molecular weight of prepolymer

- Composition of prepolymer

- Functionality of curing agent (4 for diamine curing of epoxies)

- Extent of reaction (number of dangling ends)

- Network structure (loops, entanglements, etc.)

8.3 Corothers Theory of Gelation

We begin with molecules with a reactive functionality of that are able to react with molecules with a reactive functionality of . For illustrative purposes, consider the perfectly stoichiometric case where the total functionality of all the A monomers is equal to the total functionality of all the B monomers:

We define an average reactive functionality, , so that is equal to the total number of functional groups:

The number of initial molecules corresponding to a given number of functional groups is inversely proportional to . For large values of , p does not have to reach unity in order for the total number of molecules to be reduced to one. An expression for can be obtained substituting p /2 for in Eq. , describing the evolution of with for linear step growth polymerization:

The quantity describes the average number of times that any given molecule has reacted. The number average molecular weight is predicted to diverge to infinity when this average number of reactions per molecule is 2. This occurs when , where Standardextent of reaction at the endpoint. Setting gives:

This simple equation for the gel point is very useful, although it is important to remember that this derivation suffers from the following deficiencies:

- Gelation actually occurs for finite , since only for the largest molecule.

- The theory neglects loop formation (reactions between two portions of the same molecule). These reactions change the shape of a given molecule, but do not decrease the overall number of molecules.

The first assumption tends to overestimate , and the second assumption tends to underestimate . A more accurate description of gelation requires a much more detailed theory than the one presented here.

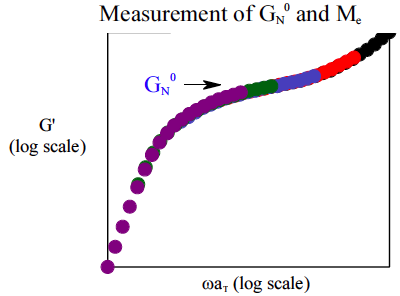

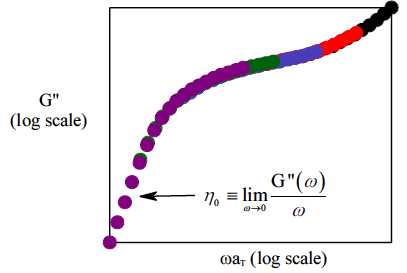

When one molecule which spans the entire sample, it can no longer flow like a liquid. One the characteristics of non-linear step growth polymerizations is that the viscosity (resistance to flow) of the reaction mixture increases as the extent of reaction increases, and eventually diverges at the gel point. Also, the reaction rate generally decreases as the reaction proceeds and the reactive molecules become larger and larger. These features are illustrated conceptually in Figure

26. Here we show schematic representations of the time-dependent extent of reaction, along with the time dependence of the number average degree of polymerization,

, and of two physical properties of the material:

and

. Here

is the limiting viscosity measured at very low shear rates, and

is the elastic modulus measured at very long times. The viscosity is a characteristic of a liquid material, and characterizes the material for values of the extent of reaction,

, that are less than the extent of reaction corresponding to the gel point,

. For values of

that exceed

, the material behaves as a solid, and has a finite elastic modulus,

. At the gel point, the viscosity diverges to infinity, since it is no longer possible for the material to flow. Instead, the material becomes an elastic solid, with a value of

that increases from 0 at the gel point.

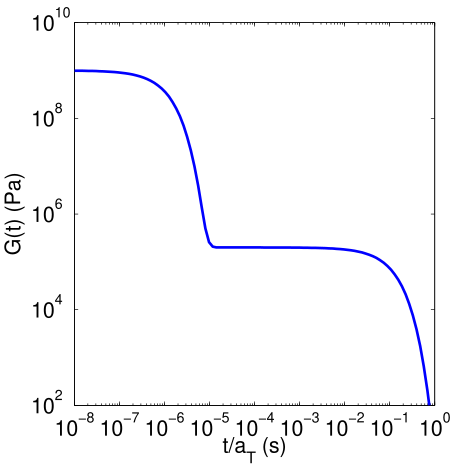

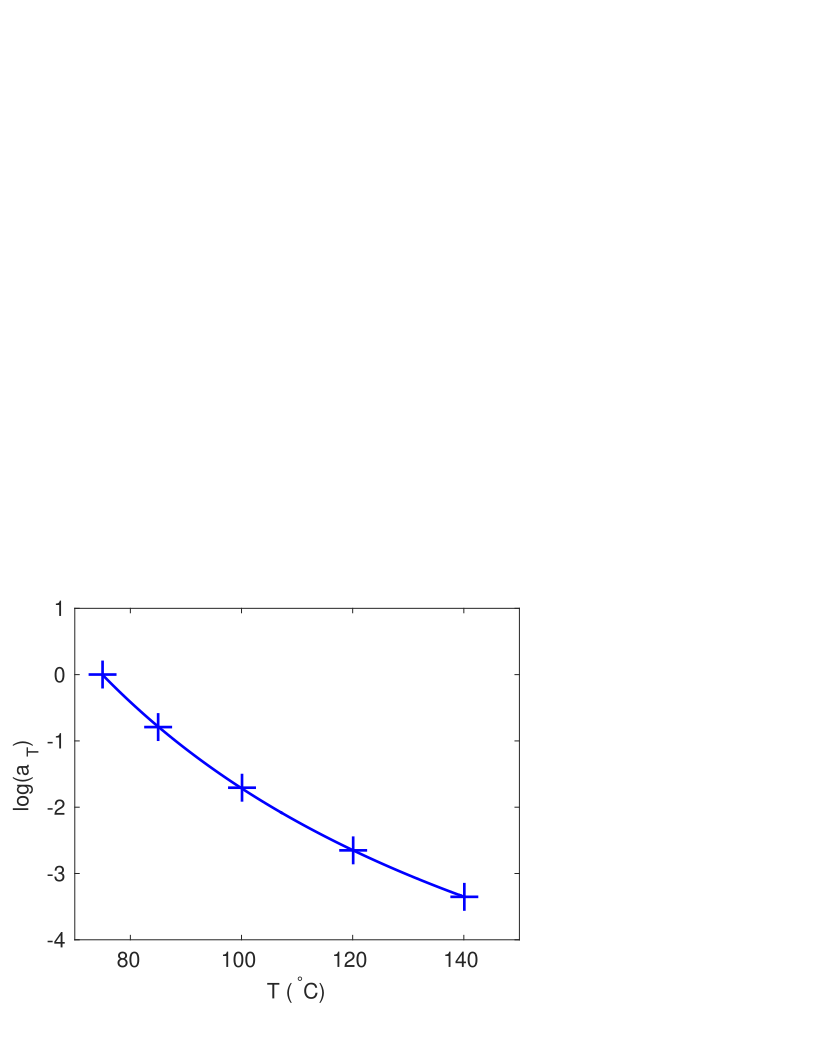

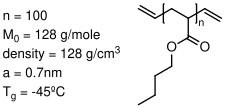

Note that that materials near the gel point are viscoelastic, and can no longer be described by a single value of the viscosity or modulus. Instead, these properties depend on the timescale of the measurement, as described in more detail on the section on viscoelasticity.

Exercise:

A very simple epoxy formulation has bisphenol A diglycidyl ether as the epoxide component and hexamethylene diamine as the crosslinker:

A) Hexamethylenediamine

B) Bisphenol A diglycidyl ether

- How many grams of hexamethylene diamine should be added to 1g of Bisphenol A diglycidyl ether in order to optimize the polymerization reaction in a homogeneous solution?

- Estimate the fraction of amine groups that need to react in order to reach the gel point.

Solution:

In this case monomer A (the hexamethylenediamine) has a molecular formula of

, corresponding to a molecular weight,

, of 116 g/mole. The functionality of monomer A,

, is 4 in this case, since each primary amine is able to react with 2 epoxide groups. Monomer B has a molecular formula of

, giving

= 340 g/mole, and a reactive functionality,

of 2. We want the total functionality of the A monomers to be equal to the total functionality of the B monomers in this case, which means that the molar quantities of A and B monomers should be related by Eq.

8.1, from which we obtain the following for

:

We have 1g of B, which we divide by it's molecular weight to get the number of moles:

So we know we need about moles of the hexamethylenediamine. Multiplying by its molecular weight of 116 g/mole gives a total mass of 0.17g. Note that we need a lot less of A than B in this case. If we want our two component epoxy to consist of two parts that we combine in nearly equal volumes, we'll have to add some extra stuff to part A (the diamine part) that doesn't take part in the curing reaction.

To figure out the average functionality, we arrange Eq.

8.2 to give the following for

:

Combining this with Eq.

8.4 for the gel point gives:

Substituting our stochiometric condition that gives .

9 Chain-Growth Polymerizations

In chain growth polymerization monomers are added one at a time to a reactive site at that typically remains at the end of the monomer that has been most recently added. There are three phases of the reaction that need to be considered in general:

- Initiation: In this step the a reactive species is formed that is able to form covalent bond with a monomer, reforming the active species at the end of the growing polymer chain.

- Propagation: Monomers are added one at a time to the growing chain.

- Termination: The reactive undergoes a reaction of some sort that causes it to lose its reactivity toward other monomers. The polymer chain is 'dead' at this point, and no longer grows in length.

9.1 Chain Growth Polymerization Mechanisms

Chain growth polymerizations generally occur either by addition to a double bond, or by opening a ring. In both cases the overall number of bonds is conserved, and there are no condensation products. If the cases where chain growth occurs by addition to double bond between two carbon atoms, the following takes place:

- A new bond is formed between the active sight and one if the doubly bonded carbons

- The double bond is shifted to a single bond.

In a ring opening polymerization, the following takes place:

- A new bond is formed between the active species and one of the atoms in a cylic monomer.

- An adjacent bond in the monomer is broken.

- The active site moves to the end of the linear molecule.

9.2 Reactive Species for Chain Growth Polymerization

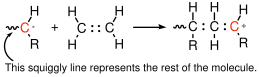

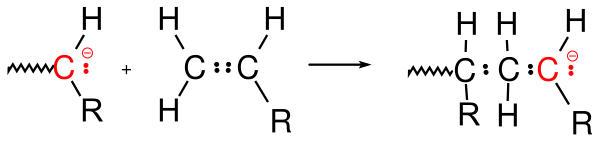

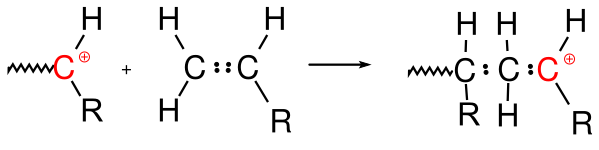

Three of the most common active sites are a free radical, negatively charged anion, and a positively charged cation, illustrated in Figure

29 for the addition to the double bond of vinyl polymers. Vinyl polymers have the general structure

, where R is something other than hydrogen. In each of these cases, a single monomer repeat unit is added to the end of the chain, and the reactive site moves to the end of the chain, on the repeat unit that has just been added. Reactions in organic chemistry are all about keeping track of what the bonding electrons are doing, and Lewis diagrams are very helpful in this sense. In the figures designed to illustrate different propagation and termination reactions, we just show the Lewis structures for some of the bonds, to make it simpler to keep track of the situation before and after the reaction has taken place. For our purpose we are not as interested in the detailed reaction mechanism, which would require that we provide a bit more information about the structure of some of the short-lived reaction intermediate.

9.3 Initiation

The previous section outlines the chemistry of some different propagation reactions, where monomers are added to an active site. Initiation is the step by which the active site is produced at the beginning. Here we give two simple examples, one for initiation of a radical polymerization, and the second being the initiation of a an anionic polymerization.

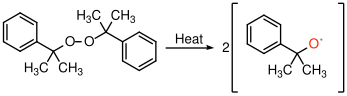

9.3.1 Initiation of a free radical polymerization

In this example, illustrated in Figure

30, a peroxide bond between two oxygen atoms splits to form two free radicals. These radicals are able to add to the double bond in a vinyl monomer like styrene to initiate the polymerization reaction.

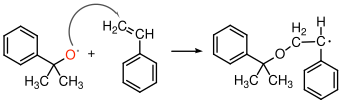

9.3.2 Initiation of an anionic polymerization

In the example shown in Figure

31 is very simple conceptually. The reaction is done in solution, and a small amount of secondary butyl lithium is simply added to a solution of styrene molecule in an appropriate organic solvent. The carbon-lithium bond is very reactive, and has a lot of ionic character. It can really be viewed as an existing anion that is ready to react directly with the styrene monomer.

9.4 Termination Mechanisms

Termination is the process by which reactive chain ends become unreactive. Termination reactions can be avoided in 'living polymerizations' like anionic and cationic polymerizations.

9.4.1 Radical Recombination

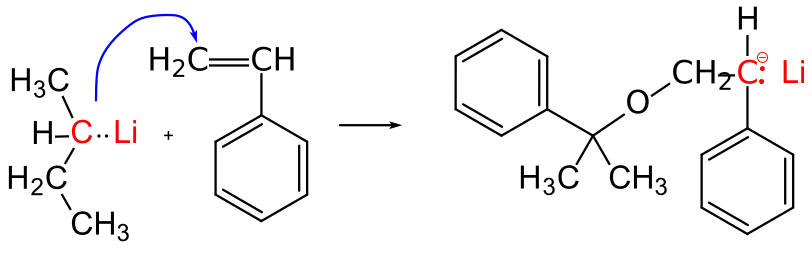

Termination reactions cannot be eliminated in free radical polymerizations, since two free radicals can always combine directly to form a single bond, as illustrated below in Figure

32.

As unpaired electrons, free radicals are very reactive towards one another. As illustrated in this example, two free radicals can readily combine with one another to form a covalent bond. Combination is therefore one type of termination reaction which is very prominent with free radical polymerizations. Note that the number of molecules decreases by one during the combination reaction.

9.4.2 Disproportionation

Plain Laytionation reactions can be viewed as the transfer of a proton andEntanglementsfrom one active molecule to another. The animation here illustrates how the transfer results in the termination of both molecules, with the formation of a double bond. In the final state, the carbon atoms all have eight electrons (including shared electrons) in the valence shell. The molecular weights of the two polymer molecules remain essentially unchanged (with the exception of the transfer of a single proton).

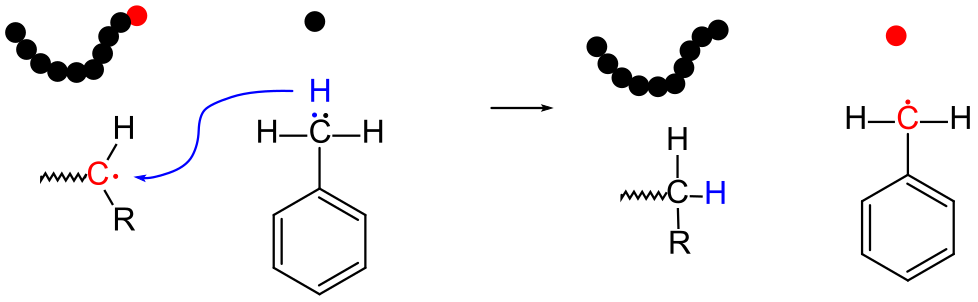

9.4.3 Chain Transfer

Chain transfer refers to the migration of the active free radical from one molecule to the other. In this example, the active radical from the growing polymer chain is terminated by the addition of a proton and an electron from the toluene molecule on the right. The net result is that the free radical is transferred from the polymer molecule to the solvent molecule (toluene), which can then initiate the polymerization of additional monomer. Note that the process is very similar to disproportionation, except that the species which donates the proton and electron does not already have a free radical.

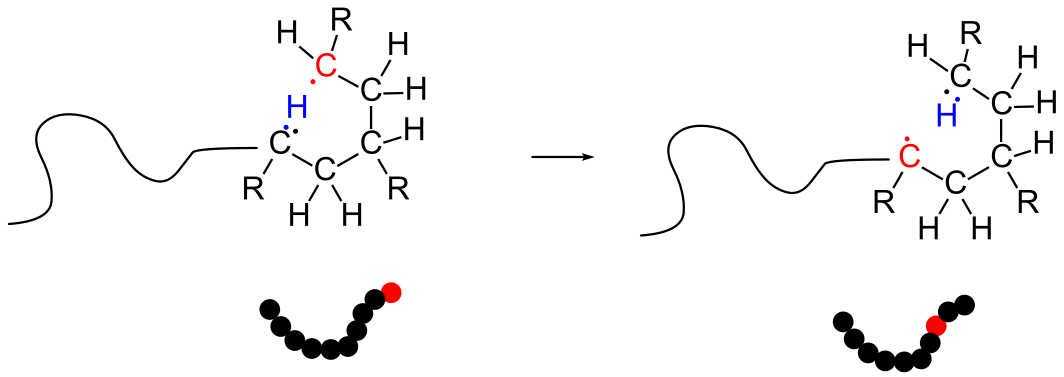

9.5 Intramolecular Chain Transfer

In this example, the active radical moves from the end of the polymer chain to a different portion on the same polymer chain. Polymerization continues from this radical, resulting in the formation of a short branch, in this case consisting of four carbons. Because the branches are randomly placed along the polymer backbone, they interfere with the polymer's ability to crystallize.

Exercise:

- Chain transfer agents, like toluene in the previous example, can be intentionally added to give some control over the molecular weights of polymers synthesized by free radical polymerizations. In a qualitative sense, how will the addition of chain transfer agents change the number average molecular weight of the polymer?

- How does your answer to this question change if the chain transfer is always to other sites within the same polymer molecule?

- Termination reactions involving free radical polymerizations involve the elimination of two radicals to form a new bond. Where does this new bond appear for combination and disproportionation reactions?

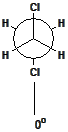

9.6 Polymerization of Dienes

Dienes are monomers with two double bonds, with a single bond between them. Examples include butadiene, isoprene and chloroprene. The situation for isoprene is illustrated in Figure

36. The monomer has 4 carbon atoms in a line, which we number 1 through 4. Double bonds connect carbons 1 to 2 and 3 to 4, and a single bond connects carbon 2 to 3. Carbons 2 and 3 are distinguishable from one another because carbon 2 is bonded to a methyl group that is not present on carbon 2. When a propagating polymer chain interacts with the isoprene monomer, addition can occur in any of 4 different ways, which are illustrated in Figure

36:

- 1,2 addition: The active chain end adds across the bond between carbons 1 and 2, just as it would in a normal polymerization.

- 3,4 addition: Like 1,2 addition, but the reaction occurs across the bond between carbons 3 and 4.

- 1,4 addition: Here the reactive site attaches to carbon 1 and the active site moves to carbon 4, with a double bond being formed between carbons 2 and 3. This double bond can exist in a 'cis' conformation or 'trans' configurations. These cis and trans configurations represent chemically different structures, resulting in polymers with different properties.

Natural rubber is a naturally occurring version of polyisoprene that is harvested from certain tropical trees. The excellent elastomeric properties of this material arise from the pure cis 1-4 microstructure that is produced during the natural polymerization of this polymer. Because of the zigzag nature of the polymer backbone, it does not readily crystallize. A segment of the backbone of the polymer is shown in Figure

37. This schematic shows a portion of the molecule in a fully extended form. Because of the easy rotation about single bonds, the molecules actually exist in a collection of random configurations.

9.7 Living Polymerizations

Living polymerizations are chain growth polymerizations that proceed without termination or chain transfer reactions. Relatively monodisperse polymers ( / < 1.1) can typically be obtained when the initiation rate is faster than than the propagation rate. Block copolymers are formed by the sequential addition of two (or more) different monomer types in a living polymerization.

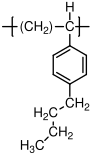

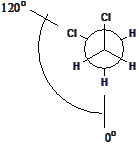

9.8 Vinyl Polymers and Tacticity

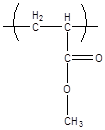

are an important class of polymers produced by chain growth polymerizations. They are produced from vinyl monomers with the following general structure:

When a vinyl monomer is polymerized and we stretch the resulting polymer chain out so that the backbone C-C bonds all lie on the same plane, the 'R' groups end up on different sides of the molecule. The distribution of these R groups determines the

, according to the following definitions:

- Isotactic:

All R groups on same side of the molecule.

- Syndiotactic:

R groups on alternate sides of the molecule.

- Atactic

R groups randomly placed.

These different tacticities are illustrated in Figure

39.

Tacticity is significant because it determines the ability of a polymer to crystallize. The disordered structure of an atactic polymer is inconsistent with the ordered structure of a crystalline polymer. As a result, atactic polymers generally cannot crystallize.Standardons to this rule include polymers where the 'R' group is very small, so that this group can be incorporated into an ordered crystalline array, even if it is randomly placed along the polymer chain. For this reason polyvinyl chloride can be partially crystalline even if the polymer is atactic. Atactic polystyrene and atactic polypropylene, however, are always amorphous.

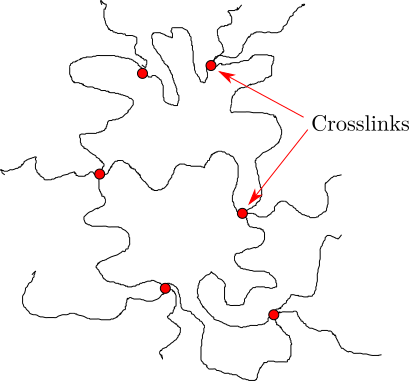

9.9 Crosslinking

Crosslinking is the process by which separate molecules in an amorphous polymer are chemically attached to one another, as shown schematically in Figure

40. The black lines indicate individual molecules, and the red dots represent crosslink points where these molecules are 'tied' together.

A representative and commercially important crosslinking system, known by the commercial name of Sylgard 184, consists of the two different parts shown in Figure

41. Part 1 consists of poly(dimethyl silioxane) polymer with vinyl groups (double bonds) at each end of the polymer molecules. Part 2 contains a silicone crosslinker with several silane groups (Si-H) that are able to react with the vinyl groups as shown in Figure

42. The reaction can be viewed as a step growth reaction involving a component with a reactive functionality of 2 (part 1) and a second component with a reactive functionality that is much larger than 2 (part 2).

10 Common Polymers

Here we list some common polymer produced by the different synthesis methods introduced in the previous sections.

10.1 Chain Growth: Addition to a Double Bond

10.1.1 Polyethylene

The simplest polymer from a structural standpoint is polyethylene, with the structure shown below in Figure

43.Dynamicity is not relevant in this case, since there are no substituents other than hydrogen on the carbon backbone.

High Density Polyethylene:

High density polyethylene refers to version with very little chain branching, thus resulting in a high degree of crystallinity. Completely linear polyethylene has a melting point of 138 °C, and a glass transition temperature near -100 °C.

C, C (perfectly linear)

Low Density Polyethylene:

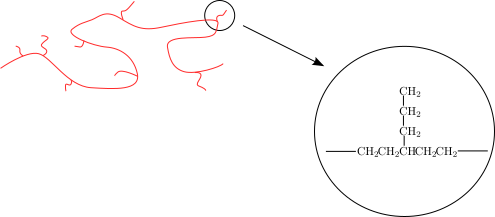

Low density polyethylenes (LDPE's) and high density polyethylenes (HDPE's) are identical in their chemical structure at the atomic level. They are actually structural isomers of one another. Chain branching within low density polyethylene inhibits crystallization, resulting in a material with a melting point lower than 138 degrees C. The decreased crystallinity of LDPE results in a material which is more flexible (lower elastic modulus) than HDPE.

The chain branches responsible for inhibiting crystallization in low density polyethylene are typically short. This illustration shows a 3-carbon (propyl) branch, potentially resulting from intramolecular chain transfer during the polymerization reaction.

C, C (depending on branching)

The Importance of Molecular Weight:

Polymeric materials generally have favorable mechanical properties only when the molecular weight is very large - typically hundreds of thousands of g/mol. The point is illustrated with polyethylene:

- M = 16 g/mol: ethylene gas

- M 200 g/mol: candle wax

- M - g/mol: milk jugs, etc.

- M - g/mol: ultrahigh molecular weight polyethylene. This materials as excellent toughness and wear resistance, and is often used as one of the contact surfaces in joint implants.

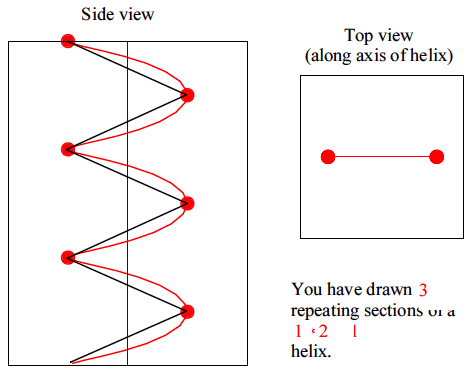

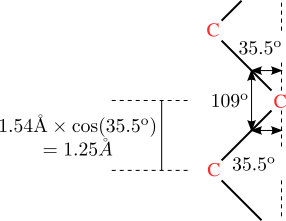

10.1.2 Polypropylene

The most widely used form of polypropylene is isostatic, with a melting point of 171 °C (for the perfectly isotactic version - a few degrees lower for the actual commercial versions), and a glass transition temperature which is well below room temperature (C). Single crystals of polypropylene have lower moduli than single crystals of polyethylene along the chain direction, because of the helical structure of propylene. The modulus of isotropic semicrystalline polypropylene is often larger than that of high density polyethylene, however, because of the details of the semicrystalline structure that is formed. The uses of polypropylene and high density polypropylene are similar.

10.1.3 Polybutene-1

This polymer included to illustrate the evolution o the polymer properties when we continue to make the side chain longer.

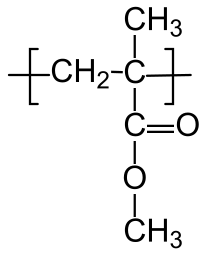

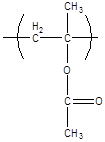

10.1.4 Poly(methyl methacrylate):

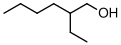

Poly(methyl methacrylate) (PMMA) is one of the most common materials used to make polymer glass. It is commonly known by the DuPont tradename Plexiglas,™ and has a glass transition temperature between 100 °C and 125 °C, depending on the tacticity. It is also forms the basis for many biomaterials, including dental adhesives.

C, no (atactic)

10.1.5 Poly(methyl acrylate)

Poly(methyl acrylate) is not a widely used polymer, primarily because it's glass transition temperature is too low ( 5 C for the atactic polymer) to be useful as a rigid polymer glass, and too high to be useful as an elastomer. It is included here to illustrate the effect that removing the extra methyl group from the polymer backbone has on the glass transition of the polymer.

C, no (atactic)

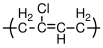

10.1.6 Neoprene

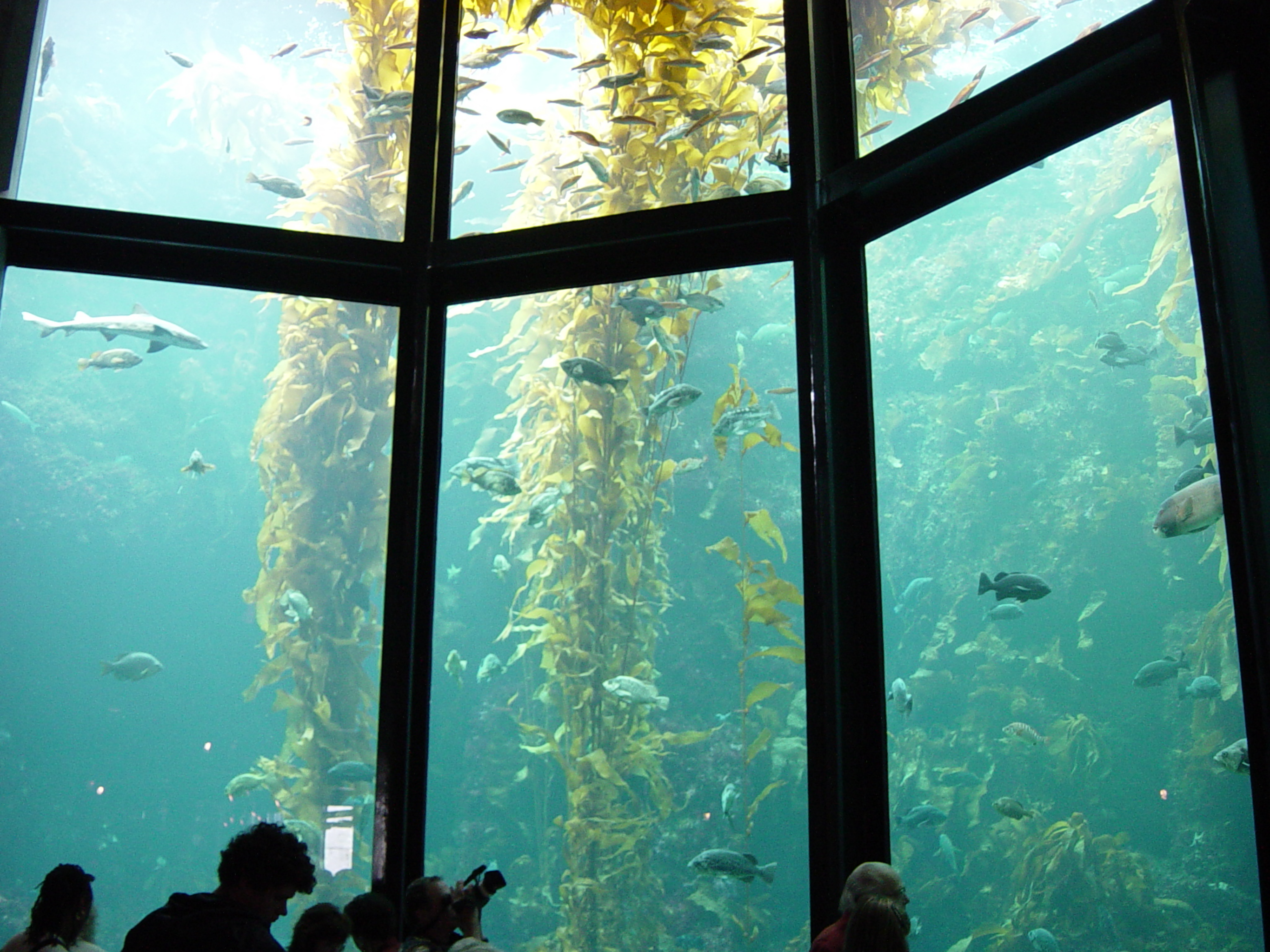

Neoprene, also called polychloroprene,

is a material commonly used in wetsuits. Like polyisoprene, it can be polymerized in different forms, corresponding to 1-2, 3-4, cis 1-4 and trans 1-4 addition of the monomer (trans 1-4 addition shown below). This pictured wetsuit has a 0.5mm layer of neoprene sandwiched between layers of nylon and another synthetic material.

10.1.7 Polyisobutylene

Polyisobutylene is a common material used to make elastomers, referred to more simply as 'butyl' rubber. It is generally copolymerized by with a small amount of isoprene, so that the resulting double bonds can be used to form a crosslinked material. It is more resistant to solvent penetration than most elastomers, and is often used in applications (like the gloves above) where barrier resistance is needed.

C, C

10.1.8 Polystyrene

Polystyrene

is almost always atactic, and therefore amorphous. It has a glass transition temperature of 100 °C, and is therefore a glassy polymer at room temperature. Its uses are typically in packing material "Styrofoam", and for making cheap plastic objects, like the vials shown above. When suitably modified by the addition of other types of polymers, it is the basis for relatively high performance plastics such as high impact polystyrene (HIPS) and acrylonitrile-butadiene-styrene (ABS).

C, no (atactic)

10.1.9 Poly(tetrafluroethylene) (PTFE)Poly(tetrafluoroethylene) (PTFE)

Poly(tetrafluoroethylene) is more commonly known by its DuPont trade name,

. Its most outstanding properties are its low surface energy and its low friction against a variety of other materials. It has very poor mechanical properties, however, and is difficult to process by its melting temperature exceeds the temperature at which it begins to degrade.

C (by one report[

7]);

C.

10.1.10 Poly(vinyl acetate)

Poly(vinyl acetate) is often used as base for chewing gum. It is glassy at room temperature but becomes softer at body temperature, which is just above .

C, no (atactic)

10.1.11 Poly(vinyl chloride) PVC

Poly(vinyl chloride) can be partially crystalline even if the material is atactic, because the "R" group in this case is a chlorine atom, which is relatively small. The glass transition temperature of the material is 85 °C, although the addition of small molecules as "plasticizers" can reduce to below room temperature. When a material is referred to as "vinyl", it is probably PVC. Record albums (before the age of compact disks) and water pipes are commonly made out of poly(vinyl chloride).

C, no (atactic)

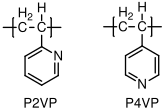

10.1.12 Poly(vinyl pyridine)

Poly(vinyl pyridine) is very similar to polystyrene, and its physical properties (entanglement molecular weight, etc.) are quite similar to the properties of polystyrene. It exists in one of two forms, poly(2-vinyl pyridine) (P2VP and poly(4-vinyl pyridine) (P4VP), based on the location of the nitrogen in the phenyl ring. Both types interact strongly with metals. The polymers are not used in wide quantities, but have been useful in a range of model studies of polymer behavior, often when incorporated with another material as part of a block copolymer.

C, no (atactic)

10.2 Chain Growth: Ring Opening

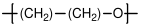

10.2.1 Poly(ethylene oxide)

Poly(ethylene oxide) (PEO) is generally formed by the ring opening polymerization of ethylene oxide. It is also referred to as polyethylene glycol, although this generally refers to lower molecular weight versions with hydroxyl end groups. PEO is water soluble, and is used in a wide range of biomedical applications, often in a gel form. Lithium salts are also soluble in PEO, and PEO/Li complexes are often used as an electrolyte in battery and fuel cell applications.

C; C

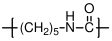

10.2.2 Polycaprolactam

:

Polycaprolactam is the polyamide equivalent of polycaprolactone, and is synthesized by the ring opening polymerization of the corresponding cyclic amide. It is often referred to as Nylon 6

, since there are 6 carbon atoms in the repeating unit of the polymer. Note that this is different than Nylon 6,6 produced by condensation polymerization, where the repeat unit has 6 carbons originating from each of the two monomers used in the polymerization reaction.

C; C

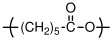

10.2.3 Polycaprolactone

:

Polycaprolactone somewhat unique in that is a polyester that is synthesized by ring opening polymerization of a cyclic ester. It can be viewed as a polyester version of the polyamide, polycaprolactam. Contrary to step growth polymerization of polyesters, the ester linkage is not formed during the polymerization reaction, but is already present in the monomer. Polycaprolactone is biodegradable because the polymer slowly degrades by ester hydrolysis over time.

C; C

10.3 Step Growth Polymers

A variety of common polymers are discussed briefly in the pages below.

10.3.1 Kevlar

™

Kevlar™ is a trademark of DuPont, Inc. The name actually is used to refer to a variety of aromatic polyamides, or aramids. As the name suggests, the polymers have phenyl groups in the backbone of the chain, and the repeat units are joined by amide linkages. The simplest possible aramid has the structure shown in Figure

59.

: above degradation temperature for the polymer.

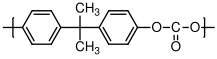

10.3.2 Polycarbonate

A variety of polycarbonates

exist. The most common one, (with the GE trademark of Lexan) has a glass transition temperature of 150 °C. It is used for compact disks, eyeglass lenses, and shatterproof glass. See

http://www.pslc.ws/macrog/pcsyn.htm for a good description of the synthesis of polycarbonate via a step growth, condensation reaction involving a phenolic di-alcohol and phosgene

C

10.3.3 Polyethylene Terephthalate (PET)

Polyethylene terephthalate (trade names include Mylar and Dacron) is produced in fiber form for textiles, and in film form for recyclable bottles, etc. Its degree of crystallinity is highly dependent on the processing conditions, since it can easily be quenched to a glassy state before crystallization is able to occur.

C

C

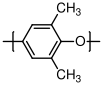

10.3.4 Poly(phenylene oxide)

Polyphenylene oxide is a high performance polymer has many varied uses, largely because of its excellent performance at high temperatures. C

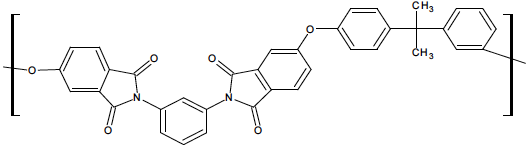

10.3.5 Ultem Polyetherimide

Ultem (a trademark of GE) is a form of polyetherimide. It is a high performance polymer that combines high strength and rigidity at elevated temperatures with long term heat resistance ( C). The repeat unit is illustrative of the complex chemical structure of many modern, high performance polymers.

10.3.6 Silicones

Silicones are an important class of synthetic polymers which do not have carbon in the backbone. Instead, the backbone consists of alternating silicon and oxygen atoms. Different classes of silicones are specified by the substituents on the silicone atoms. Poly(dimethyl siloxane)

(PDMS), with methyl substituents, is the most important silicone. Its glass transition and melting temperatures are very low, so that it remains flexible at very low temperatures. It also has a very low surface energy, and forms a hydrophobic surface that is very water resistant.

;

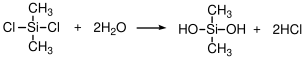

We list PDMS here as a step growth polymer because it can be produced from a self-condensation of silanol (SiOH) groups. The starting point is actually dimethyl-dichlorosilane. In th presence of water the SiCl bonds hydrolyze to SiOH:

The resultant silanol groups than can then condense by the elimination of water:

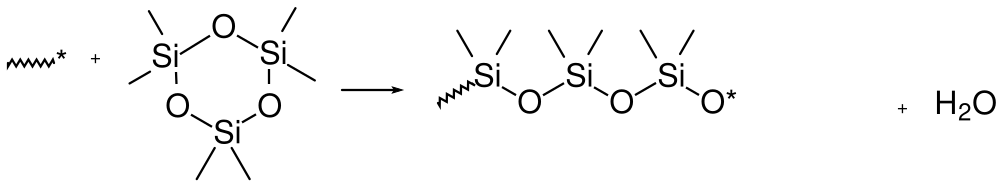

One of the interesting features of silicones is that they can also be synthesized by anionic, ring opening polymerization of cyclic, oligomeric forms of PDMS. Here's one example:

10.4 Copolymers

The polymers considered so far are homopolymers, which means they consist of a single chemical repeat unit. Copolymers consist of more than one repeat unit. Examples include

, where the different repeating units are distributed throughout a molecule, as shown schematically in Figure

68.

In

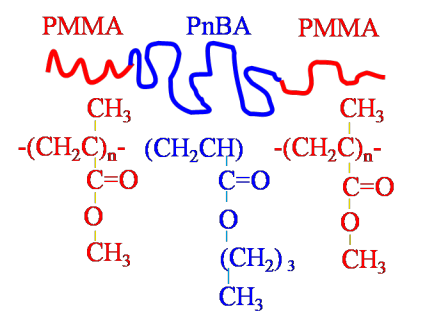

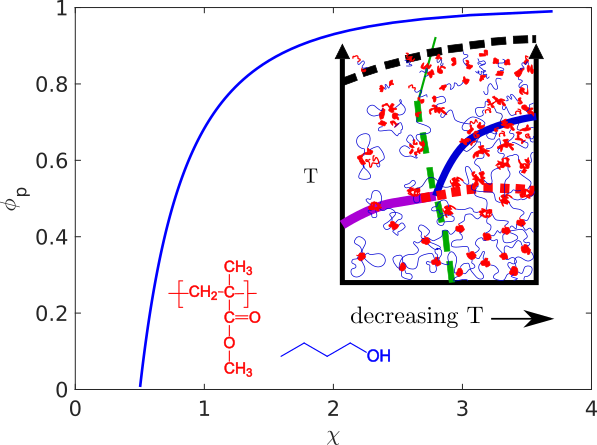

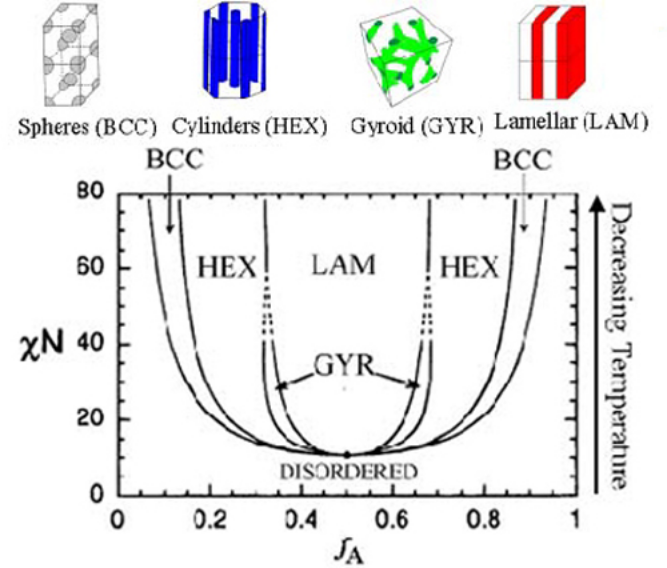

, the different repeating units appear as distinct 'blocks'. A diblock copolymer

for example, can be viewed as two different homopolymer molecules that have been covalently joined to one another as shown in Figure

69. A wide variety of interesting block copolymer morphologies have been observed. Diblock copolymers are most often synthesized by living, chain growth polymerizations.

Exercise:

Describe a procedure for making a diblock copolymer of polystyrene and poly(methyl methacrylate).

Solution:

The details of how to do this go a bit beyond the scope of this text, but conceptually we know we need to do the following in sequence: Add and appropriate initiator for a living chain growth polymerization, add monomer 'A' until all of it reacts, add monomer B until all of it reacts, terminate the reaction. Here are the details that can work for this system.

- Add an appropriate initiator. We don't want to use a radical initiator, because we need to avoid the inevitable termination reactions. From the information given in this text, either anionic or cationic polymerization. It turns out that the only anionic polymerization works in this case. We'll choose tetrahydrofuran as a solvent, clean it up very well to get rid of any impurities, and add some secondary butyllithium (see Fig. 31) as the initiator. The molar quantity of initiator will be equal to the number of moles of polymer we get at the end of the reaction.

- Add the first monomer to the initiator solution. The order matters in this case. We need to add the styrene first, and choose reaction conditions so that the initiation is much faster than the subsequent polymerization. This ensures that the polymers all have roughly the same length, since they all started polymerizing a the same time.

- Once all the styrene reacts, we add the methyl methacyrylate monomer to the solution. Because the polymerization is 'living', the active chain ends from the polystyrene part of the polymerization are still available to react with the methyl methacrylate.

- Terminate the reaction. This is very easy to do, and can be done by adding a small amount of methanol to the reaction, to produce lithium methoxide and a 'dead' chain after the proton from alcohol trades places with the lithium that is associated with the negatively charged carbon at the end of the polymer chain.

11 The Glass Transition

The information presented so far about the structure of amorphous polymers applies both to elastomers like natural rubber, in addition to engineering thermoplastics like polystyrene. The properties of rigid plastics and rubber are obviously quite different, in spite of these similarities. The difference is that below a certain temperature, molecular motion is no longer possible, and the material becomes a relatively hard solid. This transition between “soft” and “hard” behavior occurs at the

glass transition temperature

,

.

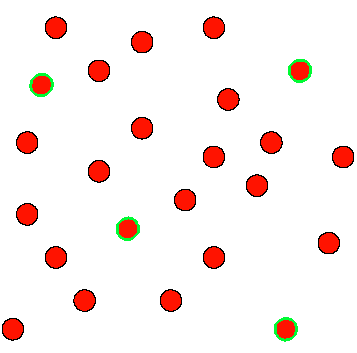

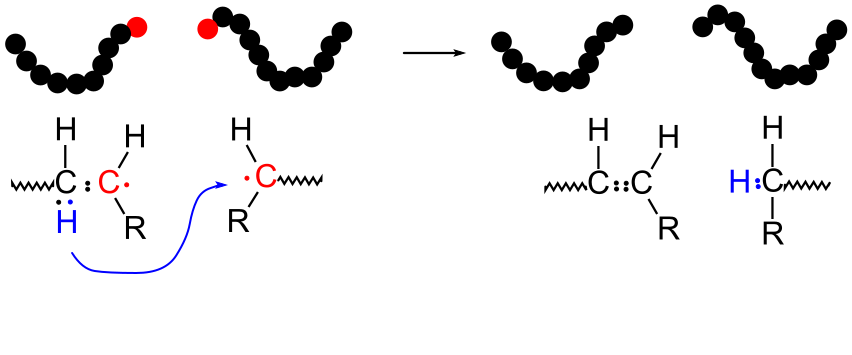

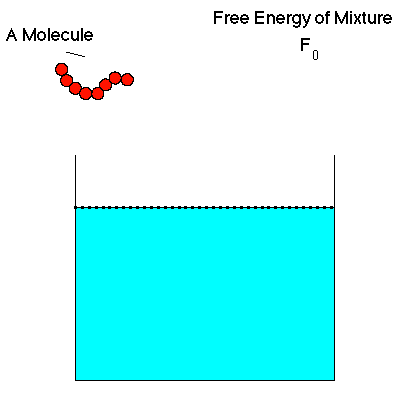

11.1 Free volume

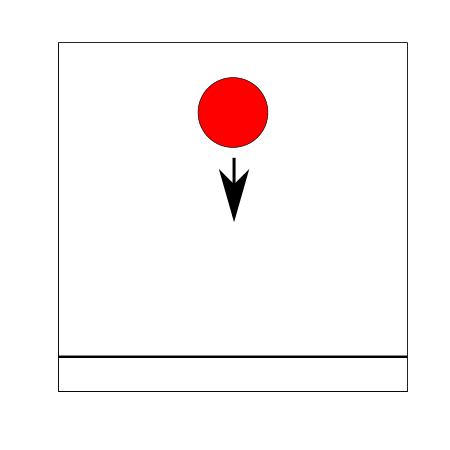

A very useful way to think about the glass transition involves the concept of unoccupied space, or 'free volume' in a polymer. This concept is illustrated conceptually in Figure

70. The red dots connected together by lines represent polymer molecules. In this lattice model of polymers, the red dots are constrained to fit on a lattice. (The lattice is completely artificial, and does not exist in reality). These dots represent the '

'

. Empty lattice sites represent

.

The lattice on the left has no free volume, so there is no way for the molecules to move by the 'hopping' of segments into a small region of unoccupied space. The lattice on the right does have free volume, however, so that molecular motion is relatively easy.

The conceptual free volume model of the glass transition makes the assumption that

volume thermal expansion coefficient

,

is defined in the following manner:

Note that the linear thermal expansion coefficient, defined in terms of the linear dimensions of the sample rather than the volume, is equal to α/3. If the fractional change in free volume is small ( ) then describes the linear relationship between the change in volume in the change in temperature:

In the glassy phase ( ), the free volume is assumed to remain constant, so that increases in the volume are governed entirely by increases in the occupied volume:

In the liquid phase ( ), the free volume and occupied volumes both increase with temperature, and we have:

Combining

11.3 and gives the following expression for the free volume in the liquid state:

Now we define a new temperature,

which is the theoretical temperature at which the free volume would go to zero, if the material were to continue to follow the liquid behavior below

. It is illustrated schematically in Figure

71. To determine the fractional free volume at the glass transition, we use Eq.

11.5 with

, recognizing that

at

:

Typically, is about 50K below the measured glass transition temperature, and the fractional free volume at is in the range of a couple percent.

The concept of free volume can be helpful in sorting out how the glass transition depends on the structure of the polymer, based on the following two guidelines:

- Changes to the polymer structure that increase the free volume needed in and r for the backbone of the polymer to move will increase . Making the backbone very still (by the incorporation of phenyl groups, as in increase . Also, bulky, 'fat' substituents (like methyl or phenyl groups) tend to increase when added to the backbone.

- Changes to the polymer structure that introduce extra free volume will decrease . This is the case for long, thin additions to the backbone, such as alkyl chains .

Without experience it's difficult to know which of these effects is greater. If I add something to the backbone for example, does it create more free volume that it needs to move? The best way to get a handle on this is to take a look at the glass transition temperatures of atactic polymers with the general chemical structure shown in Figure

72. The glass transition temperatures for these different polymers are listed in Table

1.

|

|

R =H

|

R =CH

|

|

R : H

|

-125

|

-13

|

|

R : CH

|

-13

|

-75

|

R :

|

100

|

180

|

R :

|

10

|

105

|

R :

|

-54

|

20

|

Table 1: Glass transition temperatures (in C) for polymers with the general structure shown in Figure 72

(From ref.[4]).

Exercise:

Polystyrene has a volume thermal expansion coefficient of for temperatures above , and a thermal expansion coefficient of for temperatures below . Estimate the ratio of the free volume to the total volume of sample in the glassy state. Assume that is 50K below .

Solution:

Since the fractional free volume is assumed to be fixed below

,we are looking for the for the fractional free volume at the glass transition, as given by Eq.

11.5. With

and

K, we obtain:

This value of 0.02 is a typical value for the fractional free volume in a glassy polymer.

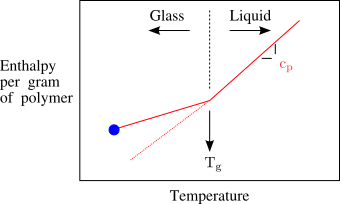

11.2 Enthalpy and Heat Capacity

The heat capacity ( ) of the liquid is larger than the heat capacity of the glass. Note that the enthalpy itself is continuous at . The glass transition is therefore a second order transition - thermodynamic quantities like volume, enthalpy and entropy are continuous at the transition but the derivatives of these quantities with respect to temperature are discontinuous.

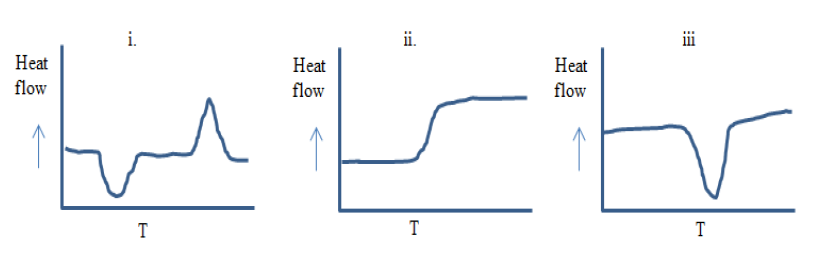

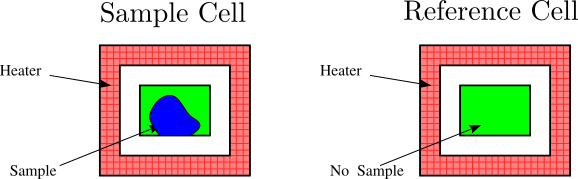

11.3 Differential Scanning Calorimetry (DSC)

Glass transition temperatures are most commonly measured by differential scanning calorimetry

. The technique can be used to measure the glass transition temperature of a polymer, in addition to the temperature at which a polymer melts or crystallizes. The heat of fusion (heat required to melt a semicrystalline polymer) can also be obtained. Heat flowing into the sample is endothermic, and heat flowing out of the sample is exothermic. We have plotted endothermic heat flow in the positive direction, and exothermic heat flow in the negative direction. Unfortunately, there is no universally followed sign convention for displaying DSC data. Sometimes endothermic heats are plotted in the negative direction. In order to avoid confusion, the endothermic direction is commonly indicated on the DSC plot, as we have done in the curve shown in Figure

75. Students are encouraged to look at the Macrogalleria web sites on the glass transition[

3] and differential scanning calorimetry[

1] for discussions at the appropriate level for this class.

12 Structure of Amorphous Polymers

Materials science is the study and application of the relationships between the properties of a material, the structure required to obtain these properties, and the processing methods which can be used to obtain these properties. Our discussion of polymer synthesis was motivated primarily by a need to understand processing methods for polymer materials. We also introduced the structure of different polymers at the atomic level, corresponding to the arrangements of individual atoms in the polymeric repeat units. Our discussion now moves to the structure of polymers on a molecular scale. We begin with amorphous polymers, and follow with a discussion of semicrystalline polymers. Ultimately, we will find that our understanding of many of the important properties of polymers can be related to these structural features by simple, yet remarkably accurate theories. In particular, the theory of rubber elasticity relates the elastic properties of an elastomer to the molecular structure described here.

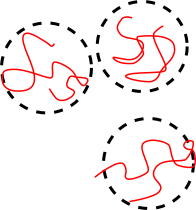

The squiggly lines in Figure

76 represent the backbones of individual molecules in an amorphous polymer. (One molecule is highlighted in red) Our goal is to relate the properties of an amorphous polymer to the distribution of shapes of these molecules. Ultimately, we will show that many of the mechanical properties of amorphous polymers at temperatures above the glass transition are related to this distribution of polymer shapes.

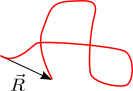

12.1 End-to-end Vector for Polymer Molecules

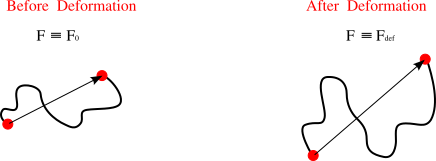

The shape of this particular molecule can only be completely specified by describing the path taken by the molecule from one end to the other. Fortunately, the most important quantity is much simpler. This quantity

,

which is simply the vector spanning the two ends of a given polymer molecule. This vector will in general be different for different polymer molecules in a sample, but the distribution of vectors can be accurately predicted. The shapes of amorphous polymer molecules are random, and random walk statistics can be used to describe the distributions of end-to-end vectors that are obtained.

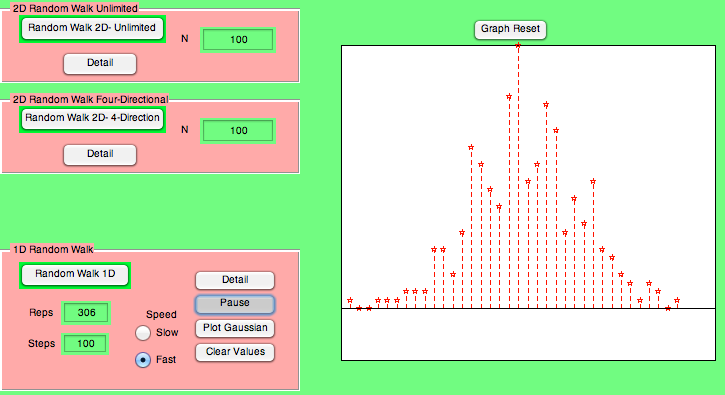

12.2 Random Walk in One Dimension

We can understand much of what we need to understand by considering the simplest case of a random walk in 1 dimension. In this case our 'walker' takes

steps, each of which is a randomly chosen move to either the left or right. At the end of these

steps we write down how many steps removed from the starting point our walker is. We refer to this number as

. For example, if the walker ends up 4 steps to the right of where he ended up, then

Where our walker ended up after one particular trip is not very important though. We need to have him take lots of trips, and collect statistics to see where he ended up after taking a large number of trips. We'll let him take a total of

trips, and write down the number of times,

that the walker has ended up

steps from where we started. If the walk is really random, then the relationship between

and

will be approximated by Eq.

12.1

We can check that the summation is appropriately normalized. In other words, is the following expression valid?

The summation here is over all possible values of . Note that for a random walk with an even number of steps, only even values of are possible. Similarly, for a walk with an odd number of steps, only odd values of are possible. We can get the summation we want by summing over all integer values of and then dividing by two:

Functions of the form (where is a constant) are called Gaussian functions, and generally describe random processes. The following integrals of a Gaussian function will be very useful for us:

In our case, , so and our expression for the Gaussian distribution of random walks is indeed normalized.

12.3 Average of a Function

The entire distribution represented by the Gaussian function will be useful to us, but it is still useful to have some averages. We encountered averages already in our discussion of the number and weight average distribution. In general, if is the probability that a discrete variable has a value of , than the average value of (referred to as ) is obtained from the following expression:

where the sum is over all possible values of . Similarly, the average of is given by:

The procedure can be generalized to calculate the average of any function of :

Exercise:

Suppose I put the following 10 numbers into a drawer: 1, 4, 8, 12, 19, 25, 28, 33, 37, 45. I randomly pick a number from the drawer and then return it. What is the average value of all the numbers that I pick if I continue with this exercise?

Solution:

We just use Eq.

12.5. Since there are 10 numbers and I am equally likely to be picked, they each have a value of 0.1 for

. So in this case we have:

In this case the answer is just the average of all the numbers, which is about as simple it gets.

In general for a function of i, where i is only able to take on discrete values, we have:

What if we have a function of a continuous variable, ? In this case, we must replace P(i), with , where is the probability that the continuous variable has a value between and . We must also replace the summation with the appropriate integral to obtain the following result:

Exercise:

Suppose I put the following 10 numbers into a drawer: 1, 4, 8, 12, 19, 25, 28, 33, 37, 45. I randomly pick a number from the drawer and then return it. What is the average value of all the numbers that I pick if I continue with this exercise?

Solution:

Calculate the average value of , assuming that x is equally likely to take on all values between 1 and 10, and that no values outside this range are possible. We know that has some constant value between 1 and 10. In order for our procedure to work, we need to make sure that the probability distribution is normalized, with In our case this gives and we get:

12.4 Averages for Random Walks

If the length of each step taken by the random walker is , then the distance between the beginning and the end of the walk is simply times this step length:

We can substitute

for

and

for

in Eq.

12.3 to get an expression for the total number of walks

We'll generalize a bit further and replace the limits of

and

for

to limits of

and

for

. We obtain the following for

, the total number of walks with values of

between

and

:

with the probability density function, given as follows:

To calculate the average values of

and

, referred to as

and

, respectively, we use Eq.

12.8 to calculate the averages:

We know intuitively that Eq.

12.11 must be true because the Gaussian distribution function is symmetric: positive and negative values of

with equal magnitudes are equally likely. This means that any contribution to

will be exactly offset by a contribution with the opposite sign. For this reason, the root mean square end-to-end distance,

, is typically used to describe the spatial extent of a random walk.

12.5 Random Walks in 3 Dimensions

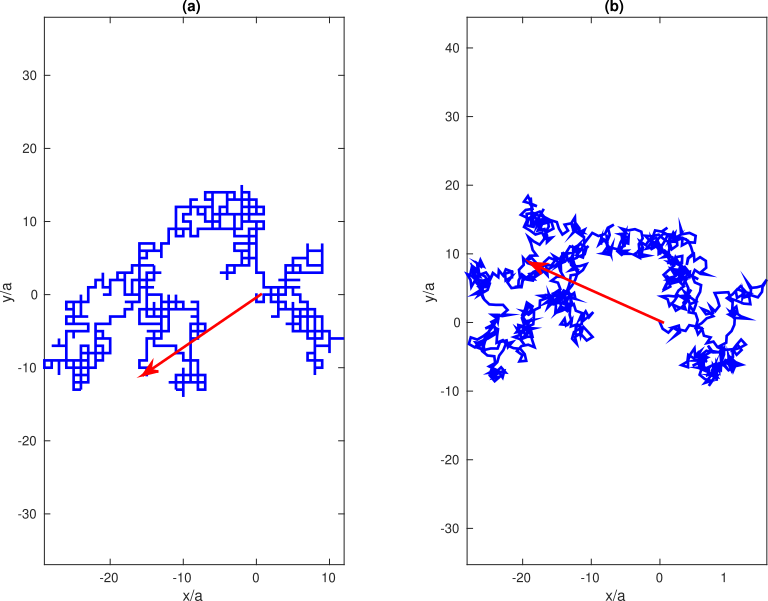

Now we can extend some of these results to describe the shapes of real polymer molecules. We begin with a discussion of two dimensional random walks. The simplest extension is to give our random walker 4 choices for his movements. In addition to moving to the left and right, he can now move up and down, as illustrated in Figure

79a. If we move the constraint that there are only 2 directions in which the walker can move, we get the example shown in Figure

79b. These trajectories are now beginning to look like the shapes of actual polymer molecules, which is why this whole exercise is relevant.

Much of our understanding of amorphous polymers is based on our treatment of individual molecules as random walks in three dimensions. We assume that we can treat a polymer of degree of polymerization

as a random walk of

steps, each with an effective length of

which we refer to as the

Statistical segment length

.

The statistical segment length does not correspond to a real polymer dimension that we can get directly by looking at the structure of the polymer molecule. We need more detailed models of chain dimensions for that. For now, you just need to know that it is a length that gives the right overall molecular size. To simplify our treatment and make the connection back to the statistics that we already developed for one-dimensional random walks, we make the following simplifying assumptions:

- We will get the overall statistics right by assuming a simple lattice model (as in Figure 79), where the a chain is able to movie in any of the x, y or z directions.

- Of the steps made by the chain, of them move in each of the x, y and z directions.

The value of that we studied in the one dimensional random walk case is just the x component of the end-to-end vector, which also has y and z components:

where , and are unit vectors in the x, y and z directions, respectively. The probability, that a given random walk of steps in three dimensions has an end-to end vector of with x, y and z components of , and is given by multiplying the probabilities for the individual components:

Here we have assumed that

and

have the same form as

from Eq.

12.10, with y or z substituting for x as appropriate. We have also used the following relationships:

along with the following definition of :

Recall that is the probability that x component of the end-to-end vector is between and , the y component is between and , and the z component is between and . We can also define a probability density where is the probability that the magnitude of the end-to-end vector lies between and Because the probability only depends on for an isotropic system (as must be the case for a truly random walk), we can substitute for to obtain:

Note that

is the average of

, obtained from the following version of Eq.

12.8:

Note that the distribution is normalized: .

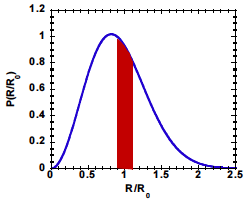

Exercise:

What fraction of molecules in an amorphous polymer have end to end vectors that are within 10% of ?

Solution:

We define a new variable,

such that

. With this definition of

, rewrite Eq.

12.18 in the following way:

Note that this expression for is normalized, with We need to integrate the probability density from =0.9 to = 1.1:

This corresponds to the shaded area in the following figure:

Numerical integration of the equation above gives = 0.18, which corresponds to the red shaded area. This is the total fraction of molecules with R between 0.9 and 1.1 .

13 Models of Chain Dimensions

Our discussion of random walk statistics tells us what the shapes of the molecules look like when we know the statistical segment length, but it doesn't tell us what the statistical segment length actually is for a particular polymer. Clearly the statistical segment length must be related to the detailed chemical structure of the repeat unit itself. For example, we wouldn't expect that polyvinyl chloride and polyethylene terephthalate would have the same statistical segment length, based on the very different chemical structures of these polymers. To obtain a prediction for the statistical segment length we need to zoom in and consider the actual backbone bonds that are connecting the polymer together. In general every bond is vector,

with a length and an orientation. As illustrated in Figure

81, the end-to-end vector is obtained by adding up all

bond vectors (

=12 in this example):

13.1 General Considerations

We are interested in the average magnitude of the end-to-end vector. As discussed in the previous section, the average of itself is not useful, since it just averages to zero. We are interested in the average value of the square of the magnitude of the end-to end vector. This quantity is equal to the dot product of the end-to-end vector with itself:

The dot product has terms, which can be represented in the following matrix form:

The dot product between two vectors,

and

is given in general by

where

is the angle between the two vectors, illustrated below in Figure

82. At this point we will make our first simplifying assumption, which is that the lengths of all bonds along the backbone are identical. This assumption is certainly valid for vinyl polymers, and other polymers which have only C-C single bonds along the backbone.

If this bond length is , then can be represented as follows, where is the angle between bondi and bondj:

The average value of R, will be determined by the average values of θ In mathematical terms, we have the following expression:

In more compact notation we can write:

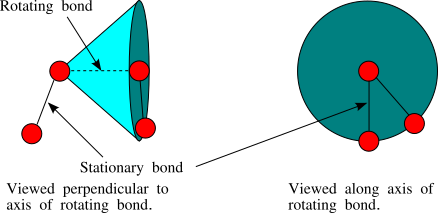

So we have reduced the problem to figuring out what the values of are in the system. This requires a specific model of how the bonds are joined to one another. In the following sections we consider two specific models (the freely jointed and freely rotating models), and a general model where the bond rotation angles are constrained.

13.2 Freely Jointed Chain Model

The simplest (and most unrealistic) model of chain dimensions is the freely jointed chain model, where all bond orientations are equally likely. In the freely jointed chain model for , because orientations giving positive and negative values of are equally likely. The only exception is for the diagonal terms for which . These represent the projection of a vector onto itself, and all have and .

13.3 Freely Rotating Chain Model